We needed ventilation in the workshop and we made a smart supply and exhaust system.

The system consists of several components:

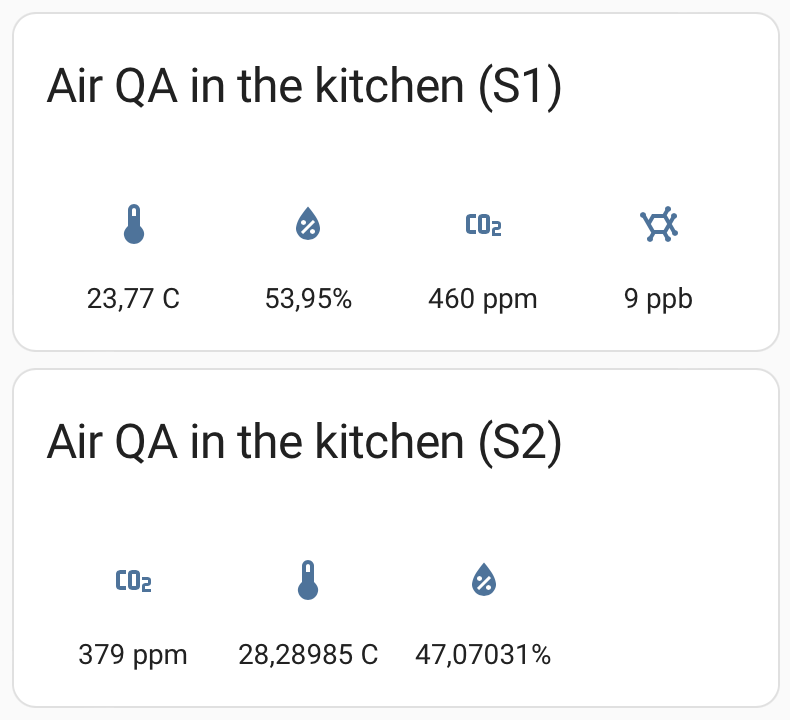

- temperature and CO2 sensors

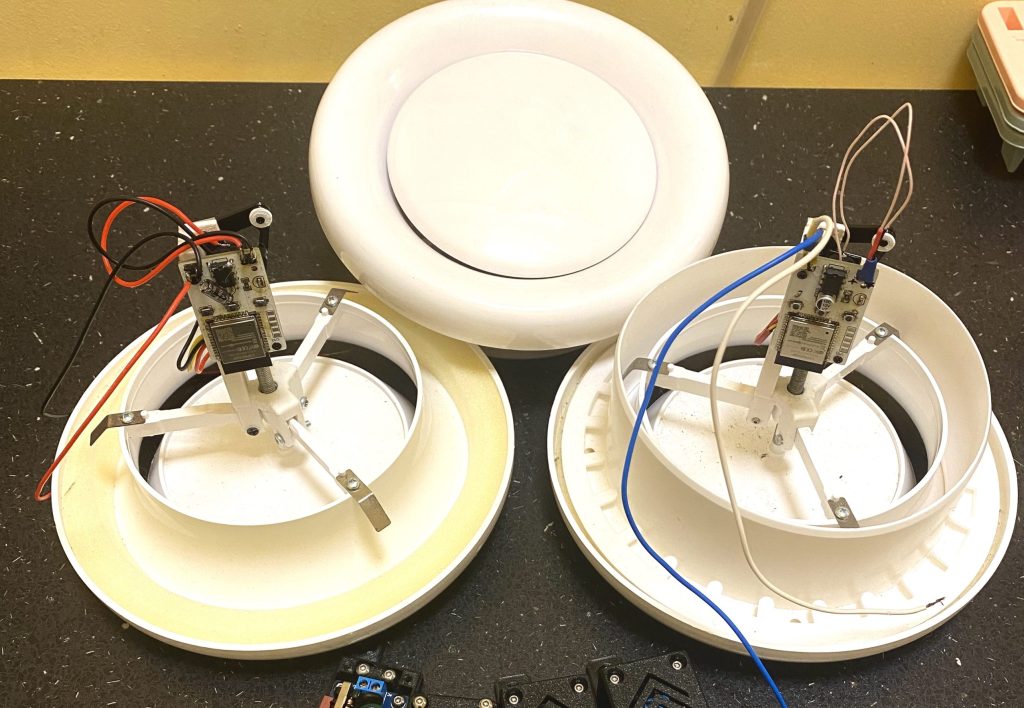

- controlled anemostats (flaps)

- air flow sensor

- inflow filter wear sensor

- relay for turning on air pumps

- control system

- IR air conditioner control module

The consumption of oxygen supplied through the ventilation is not uniform throughout the workshop.

Based on the data of the CH2 sensors the control system understands where it is worth supplying more incoming air.

There are ready-made sensors of various quality, which had to be tested and, on the basis of some of them, air quality sensors were made.

So the system controls the degree of air valves – anemostats. Off-the-shelf managed stubs are quite expensive components and only exist in professional systems. We had to design our own based on cheap hand-operated anemostats.

In the dashboard of the root control system, we can view current and historical air indicators.

The air flow sensor based on tensor sensor. It helps to track of the system.

And the filter wear sensor is based on measuring the pressure difference

Additionally, there is a control of air conditioners (which are not physically connected with ventilation air flows) through IR modules.

All system components communicate via Wifi, i.e. require only DC power supply at the location.

A little later we will talk more about transparent air pipes.